The brickwork around all fireplaces and flues should be laid with cement mortar, as it is more resistant than lime mortar to the action of heat and flue gases. -- from the USDA Farmers' Bulletin No. 1889, FIREPLACES & CHIMNEYS, December 1941

Non-concrete mortars, especially those composed of lime did not hold up well to rains, and later cement mortars were recommended. Mortar deteriorates for various reasons, one is due to the expansion and contraction due to the hot smoke from fires in the fireplace. If enough mortar fails, bricks can fall out. The chimney is likely to remain standing, but small gaps between brick and mortar can allow hot gases to pass, and risk causing adjacent combustible material to ignite, or permit cooler outside air in that disrupting the draft. The construction of unlined chimneys continued into the first half of the 20th century, but the transition by those in the industry to cement mortars made masonry chimneys more durable; also many chimneys were lined with terra cotta liners during this time which provided some protection to the masonry from rapid temperature changes.

Although, to save expense, chimneys are built without flue lining, those with linings are more efficient. When the flue is not lined, the mortar and bricks directly exposed to the action of fuel gases disinte- grate. This disintegration and that occurring from changes in temperature frequently cause cracks in the masonry, thereby reducing the draft. An unlined chimney is best if not plastered except at the sloped section. However, the vertical and horizontal joints should be filled with mortar and struck smooth and flush with the wall. Offsets or bends in flues should not be greater than 30 degrees with the vertical. This slope can be obtained by offsetting or corbeling each brick course only 1 inch.

Flue lining must withstand rapid fluctuations in temperature and be resistant to the action of ordinary flue gases. ... Place each [tile] length of flue lining in position, setting it in mortar with the joint struck smooth on the inside, and then lay the brick around it. If the lining is slipped down after several courses of brick have been laid, the joints cannot be filled and leakage is almost sure to result. Fill any spaces between the lining and the brickwork completely with mortar, especially if the round type of flue is used.

-- from the USDA Farmers' Bulletin No. 1889, FIREPLACES & CHIMNEYS, December 1941

Many unsatisfactory heating plants and much excessive fuel consumption are due to improperly constructed chimneys, which are the rule rather than the exception. -- USDA Farmer's Bulletin No. 1230, CHIMNEYS & FIREPLACES, December 1921

"Excessive fuel consumption" occurs when there is too strong a draft and when there is too weak a draft; too strong of a draft burns coal and firewood hotter and faster than is needed, and too weak of draft causes coal to burn at lower temperatures causing incomplete combustion of both volatiles and char. In the case of open fireplaces with too strong of a draft, the flue height could be lowered, but all flues served by the same chimney must be considered, along with the need for a strong enough draft in the warmest part of the heating season to function appropriately. Alternatively, and an unlikely fix may be to instead increase the cross section size of the flue. In the case of open fireplaces with too weak of a draft, the initial remedy is to ensure that the flue is air tight along its length as gaps along the brick work in an unlined flue or gaps between tiles in a lined flue may allow cold air into the stack "checking" the draft, a mason may be able to patch these gaps. On a flue with no leaks, adding height usually increases draft strength. Alternatively, and an unlikely fix, if the there are no issues with smoke escaping into the room, the flue may be narrowed. A modern fix involves using a metal liner that is retrofitted; and/or a powered vent installed at the top of the flue.

Chimneys defective in construction or badly located cause many failures of heating systems. Air passes up the chimney flue with a spiral movement; therefore a round, smooth flue is preferable because it offers less resistance to the upward passage of the gases. For structural reasons and because of the increased cost it is not nearly so common as the square or rectangular flue. The square is preferable to the rectangular. Many chimney flues are not lined. That is a mistake. The first cost of a lined flue is greater, but the benefit is not only better furnace operation but continual fuel saving; moreover the danger of fire is lessened.

The most efficient chimney, as far as draft is concerned, is one built perfectly straight from the bottom up with a round or nearly round flue, lined with tile or having the interior surface made smooth by other means. There is no advantage in tapering the inside toward the top. The cross section and height are determining factors of efficient service. The transverse area must be sufficient to pass the volume of air required to burn the fuel properly, and the height must be great enough to produce sufficient draft and insure against interference by adjoining buildings or projections of the same building.

In a square or rectangular chimney the corners are dead. The effective area in square flues is 85 to 90 per cent, and in rectangular flues about 75 per cent.

-- from USDA Farmers' Bulletin No. 1194; Feb 1923

There are various causes for well drafting flues to lose draft. Already mentioned is the lime mortar that is not as robust as cement mortars. Another cause is too thin of walls constructed on chimneys that are tall above the roof, where due to the toppling effect of strong winds the mortar bonds can fail leaving behind small air gaps or a worst case scenario that the top of the chimney may fall off; the remedy of which is either a rebuild the chimney with thicker walls or tie the chimney top to the roof using metal rod anchors.

Chimney Flues for Heating Apparatus should be ample in size, and carried as straight as possible from a point near the cellar floor to above the highest projection of the roof. They should be independent, having no connection with other flues or openings, and always of the same area from top to bottom. A well jointed tile flue, preferably round, is better than a square brick flue of larger area. The chimney flue should be carried 3 or 4 feet below the smoke pipe entrance and provided with a clean-out door at the base, tightly fitted, affording easy access for removing the accumulated dust and soot. -- from CARTON FURNACES, 1897 Catalogue and Price List, The Carton Furnace Company; section on "Chimney Flues." under heading "Hints to Architects and Builders." marked page 43

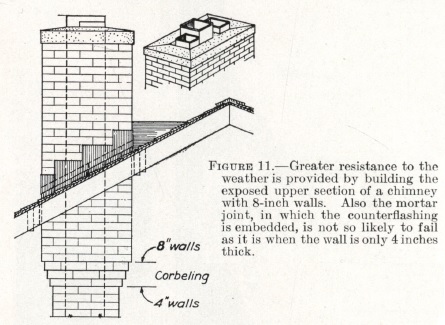

Chimneys extending above the roof are exposed to the wind and may sway enough during a gale to open up the mortar joints at the roof line. Openings in a flue at this point are especially dangerous because sparks from the flue may come in contact with the woodwork of the roof. It is therefore good practice to make the upper walls 8 inches thick (fig. 11) by starting to offset the bricks just below the intersection with the roof.

This depiction of thicker brick course to resist the wind is illustrated in the USDA Farmers' Bulletin No. 1889, FIREPLACES & CHIMNEYS, December 1941.

This chimney top was constructed with thicker brick courses from the top to just below the roof line, to resist strong winds. Note that the brick course is thicker beneath the roof line higher on the left side than on the right side of the chimney, but both sides start below the roof.

This is the typical tie rod I see, slender and straight.

This house has a large pipe shaped chimney tie rod.

This chimney has a band around the masonry midway up, and with two braces.

This side chimney has a straight and somewhat decorative tie. Most of the decoration is about midway along the tie rod, and is partially obscured from view by the chimney due to the angle that I was able to get the photo.

This, guessing is a 1940s house, has a bent tie. In comparison to straight ties, it seems to me that bent ties are uncommon, but of those bent ties that I have seen were also on houses of the same era.

Once while on vacation, we drove by a house that had a tie rod at an angle, also with some decoration. I didn't have the opportunity to go back and get a picture, but here is a depiction of how it was installed. The decoration was roughly where the star is in this drawing. What stood out to me about this configuration is that the higher the tie rod is tied into the chimney, the more of the chimney is then horizontally supported, but on that house the tie was not that far up the freestanding portion of the chimney.

This tie rod has decoration, the decoration appears to be bent flat steel stock. There is also a decorative washer on the opposite side of the chimney stack.

Lining chimneys make for a smooth surface that offers less resistance to exhaust gases, which also improves the draft that the chimney develops. Lined masonry chimneys have less edges to resist the exhaust gases as they travel up the flue, brick chimneys could be plastered with mortar as a liner but this was rare and did not resist temperature fluctations as well as terra cotta liners. For masonry chimneys, since the 19th century, terra cotta liners have become the preferred lining choice. Typically terra cotta liners come in sections and are mortared together when installed, this prevents air intrusion along the liner keeping the draft strong; additionally terra cotta liners are nearly impervious to the exhausts of all residential fuels. An important factor for a chimney to develop draft is the difference in temperature between the outside air and that of the exhaust gases passing through the flue. Depending on the material of the liner, a liner can also provide some insulation from the bricks or blocks of a masonry chimney. The exhaust gases convect some of its energy to the sides of the flue, therefore keeping the chimney as warm as possible maintains a stronger draft. In an unheated house with a functional chimney, with no ventilation systems running such as an exhaust fan or clothes dryer, the factor in maintaining draft is how well the heat of the exhaust gases are maintained in the flue; in heated houses another factor affects how well a chimney drafts, more on that later.

Metal chimney pipes can also lose draft due to seams not being airtight. Metal chimney pipe requires support and bracing, particularly sections above the roof that are subjected to winds, but where along the chimney depends on the specific product. Another cause with metal chimneys is that flyash deposits from burning coal attract moisture, which becomes acidic causing pitting that eventually eats through the metal wall. Some grades of steel used to make stove pipe are more resistant to acid, regardless it is recommended to sweep and clean metal flues as soon as the heater or fireplace is shutdown in the spring. The fix for corroded metal chimney pipe is to replace it.

Gases formed by burning the sulfur contained in coal are the main cause of corrosion of metal smoke pipes. Little corrosion occurs during the heating season, when the pipe is kept hot and dry. -- from the USDA Farmers' Bulletin No. 1889, FIREPLACES & CHIMNEYS, December 1941